Electrolysers consume lots of electricity. Why not optimise the load profile? Our optimisation models allow dispatching of the electrolyser stacks based on electricity prices, product storage, flexibility in control systems, supply contracts and more.

Any electrolyser, whether based on alkaline, PEM or solid oxide technology, can be optimised for energy usage. The key ingredients of our dispatch tool are physical models of the cell stacks, combined with optimisation of product flows and electricity consumption.

ENTRAS develops advanced optimisation algorithms to enhance electrolyser dispatching. If you are interested in a feasibility study, feel free to contact us!

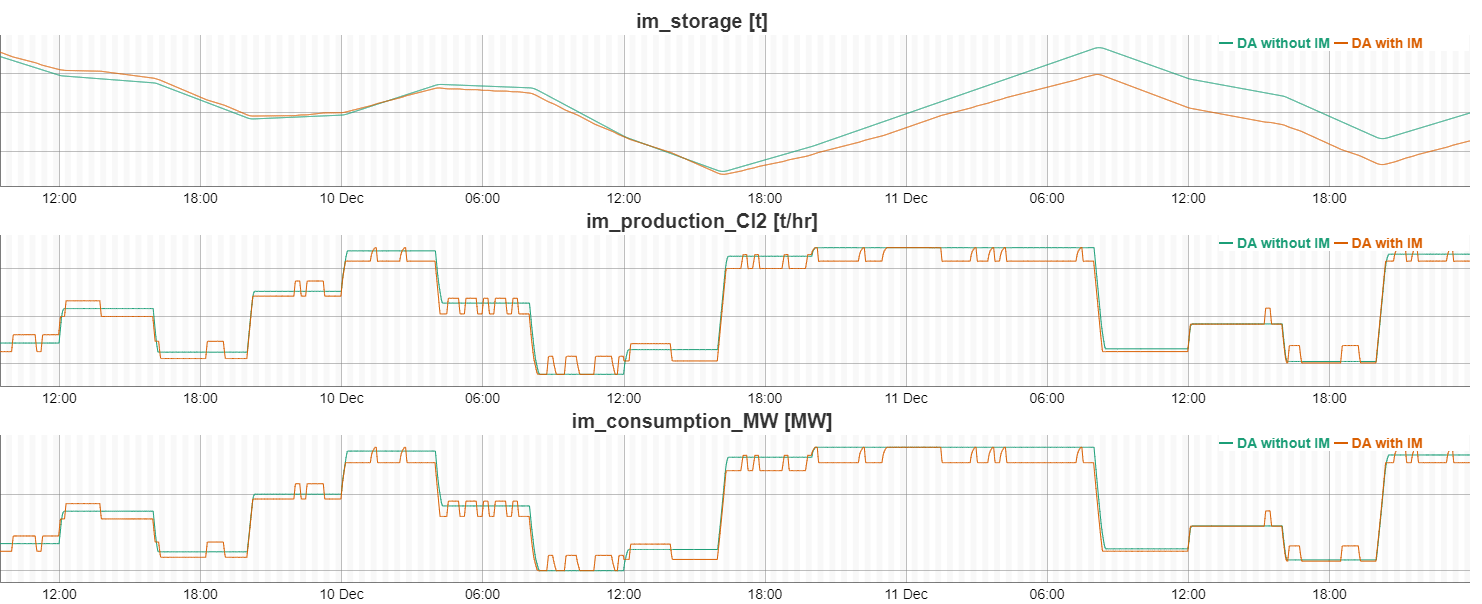

Example of combined Day Ahead and Imbalance dispatching of an electrolyser with additional product storage